III. Refining and Casting Stages

Gas Regulation in the Refining Furnace: During the metal refining process, specific gases need to be introduced into the furnace to remove impurities and adjust the composition. The gas flow regulating valves and check valves of AnyTorK play a key role in this link. The flow regulating valves can precisely control the flow rate of gases such as argon and nitrogen according to the requirements of the refining process, ensuring that the reactions in the furnace proceed at the predetermined pace. The check valves prevent gas backflow, avoiding damage to the gas supply system caused by the backflow of high-temperature and high-pressure gases in the furnace, ensuring the safety and stability of the refining process, and improving the purity and quality of metal refining.

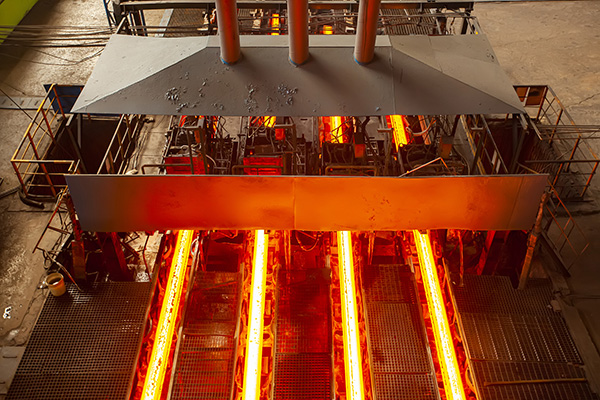

Precise Control of the Casting Process: Casting is a key step in transforming liquid metal into solid products. The electric regulating valves of AnyTorK are installed at the outlet of the casting ladle. Through the automated control system, according to the size, shape of the mold, and the requirements of the casting speed, the outflow amount of the liquid metal is precisely controlled. During the continuous casting process, it ensures that the liquid metal is uniformly and stably injected into the mold, avoiding problems such as flow interruption and uneven flow, ensuring the consistency of the casting quality and the surface finish, increasing the product qualification rate, reducing the scrap rate, and improving the production efficiency of metal smelting enterprises.